Our expertise

Our center specializes in diagnostics and medical devices including electrochemical biosensors and microfluidics. We use advanced techniques such as photolithography, soft lithography, and xerography to microfabricate microfluidic components, such as microchannels and microneedle arrays. Furthermore, we produce custom electrodes for the development of biosensors.

History

Prince of Songkla University has been an active player in the development of robust, ultrasensitive biosensor platforms for low-volume specimens, several of which have been successfully deployed for low-volume detection in food production and medical applications. To accelerate the advancement of our technologies and expansion of the application range to include other targets, such as proteins with diagnostic implications, we established a standardized laboratory equipped with cutting-edge instruments, certified to meet relevant standards. The ultimate goal is to leverage our expertise in biosensor and microfluidics to build prototypes from promising research outputs. Subsequent commercialization of these technologies is expected to provide a multitude of positive impacts, including reduced importation of medical devices, increased accessibility to high-quality medical devices, improved quality of diagnosis and treatment, and ultimately better quality of life for Thai people.

Rationale for Establishing

In order to improve the quality, accessibility, and efficiency of health and medical services for Thai people, the government considers it a priority to improve research capabilities in the medical science and public heath sectors. This includes the recruitment of skilled workforce, procurement of cutting-edge equipment, and establishment of the collaboration between domestic and international organizations, particularly in the prevention and treatment of important diseases.

In line with the government's policy described above, the Research Development Office of Prince Songkla University, in collaboration with researchers from the Faculty of Medicine, submitted the proposal to build a laboratory certified with the ISO13485 standard. This laboratory will provide advanced facilities and skilled personnel to support the research and development of prototype microfluidics and biosensors, to obtain products with exceptional sensitivity, specificity and dynamic range. Beyond building prototypes, the laboratory established will be capable of supporting the preparation of diagnostic products for commercial scale production.

The biosensor technique is an analytical method that measures chemical changes resulting from interactions between biological materials and target analytes. These changes can be converted into electrical signals that are proportional to the quantity of the target species, allowing for quantitative outputs. This technique has been increasingly adopted in the development of medical diagnostics due to its rapidity, high accuracy, reliability, and ease of use. To implement biosensors as point-of-care diagnostics, the platforms may also be miniaturized by incorporating microfluidics, which will drastically reduce the sizes of the devices as well as the amounts of samples and reagents required. This, in turn, lowers the cost per assay and enables faster operation by minimizing the steps involved in sample delivery and preparation.

To ensure the quality and safety of medical and diagnostic innovations, it is crucial to establish a standardized laboratory with effective quality control strategies in place. In addition, such a laboratory should not entirely focus on designing and building devices, but also play active parts in downstream operations including sales, installation, and follow-up services. Our center was founded to fulfill these objectives, and thus far, our operations have led to the development of promising prototypes, such as a sperm sorter designed for the selection of high-quality sperm for intrauterine insemination.

Objectives and scope

The Medical Biosensor Laboratory is equipped with high-quality resources and instruments that meet the ISO 13485 standard. Our primary goal is to develop prototypes for medical devices utilizing ultrasensitive biosensing and microfabrication technologies, with a focus on preparing them for clinical applications. To date, we have developed a range of successful prototypes including a lactate detector, sperm sorter, biosensor for indicators of acute renal failure, blood cell sorter, cancer cell sorter, cell-on-chip platforms for drug testing, among others

Collaborations

Southern Science Park, Prince of Songkla University, Hat Yai campus, Songkla province

Products and Services with International Standards

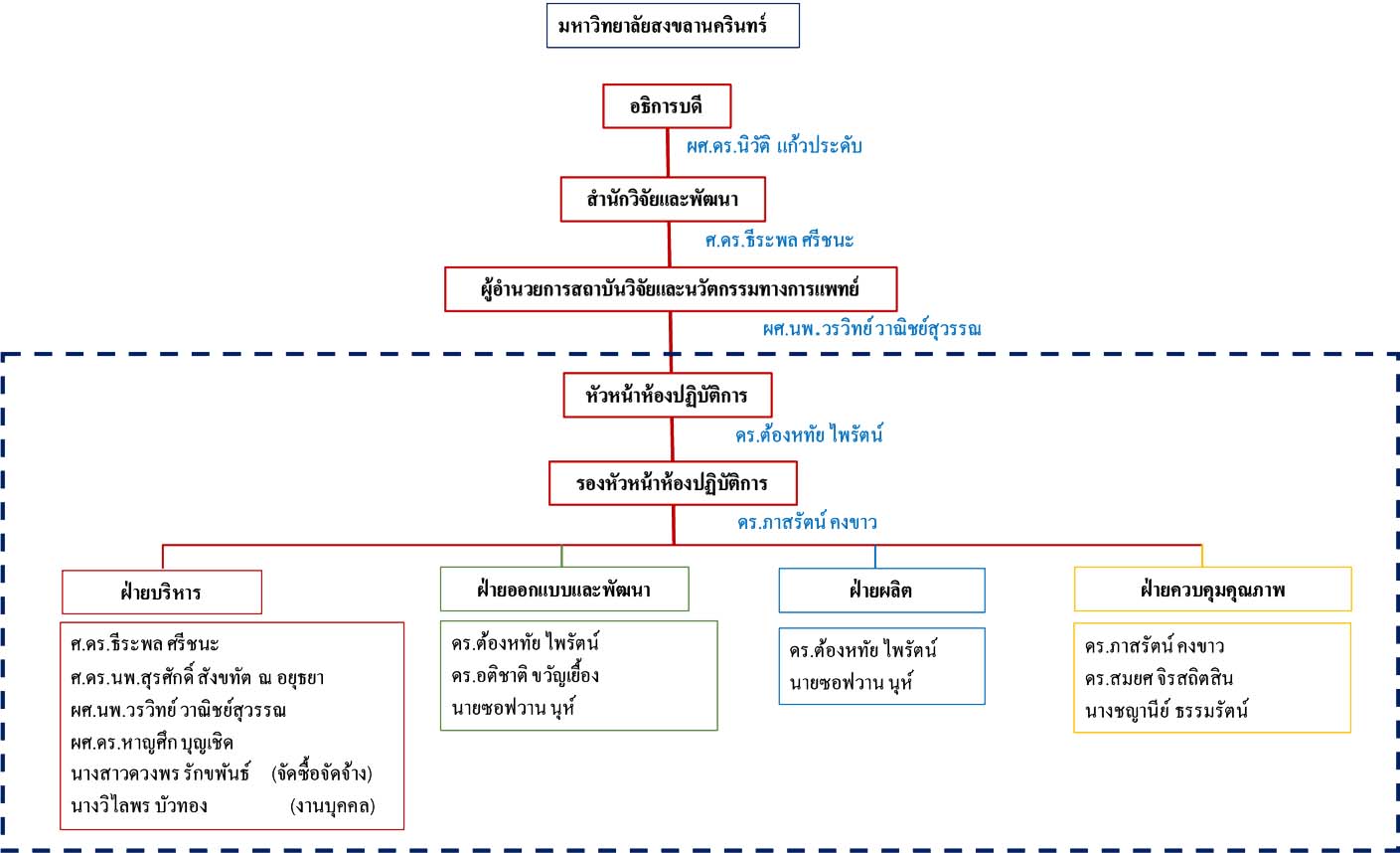

Our laboratory has obtained the ISO 13485:2016 certification, ensuring that our products, raw materials, and production facilities meet the required standards.Organizational chart

Products and Innovation

Lactate detector for septicemia patients

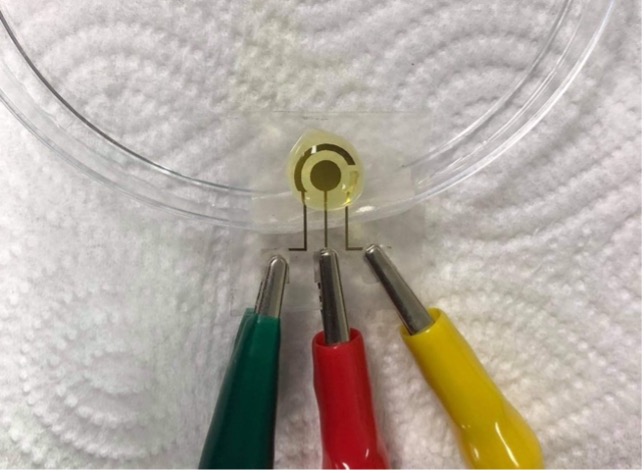

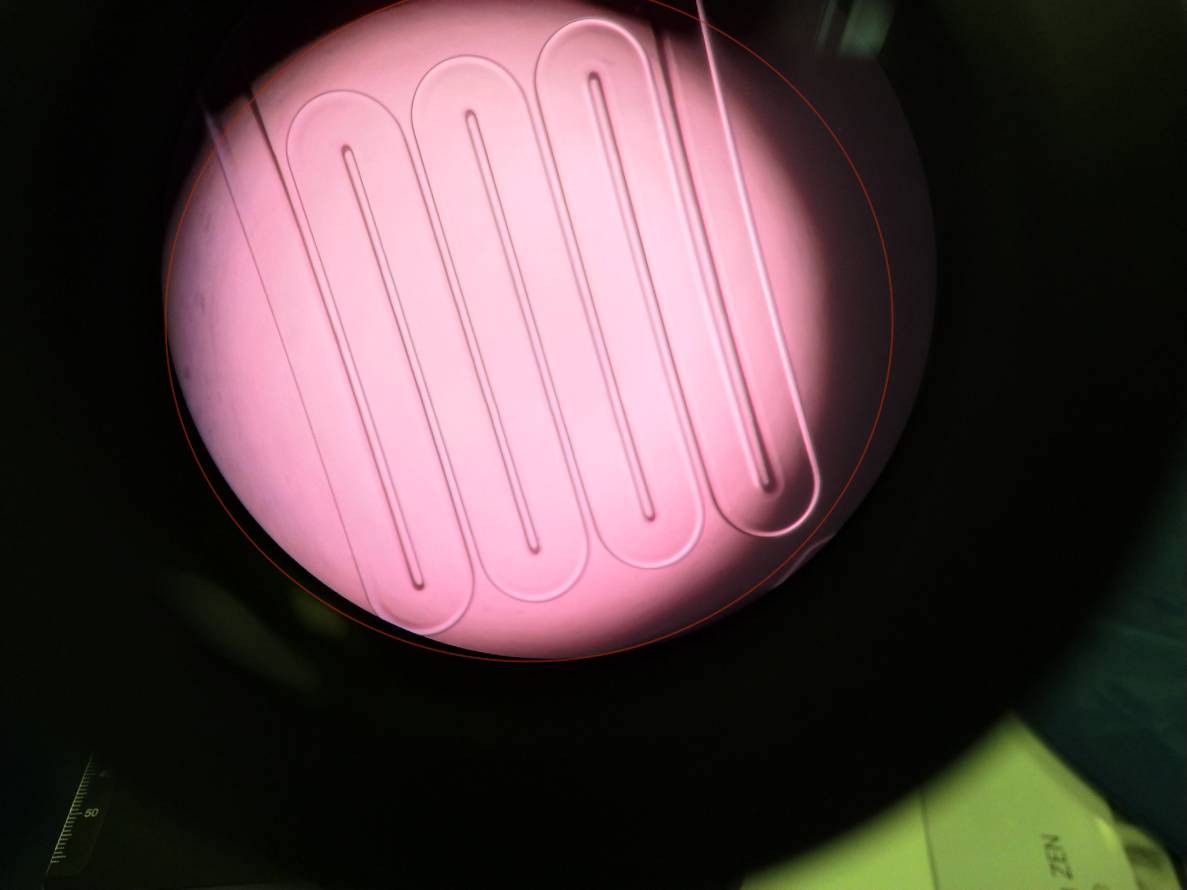

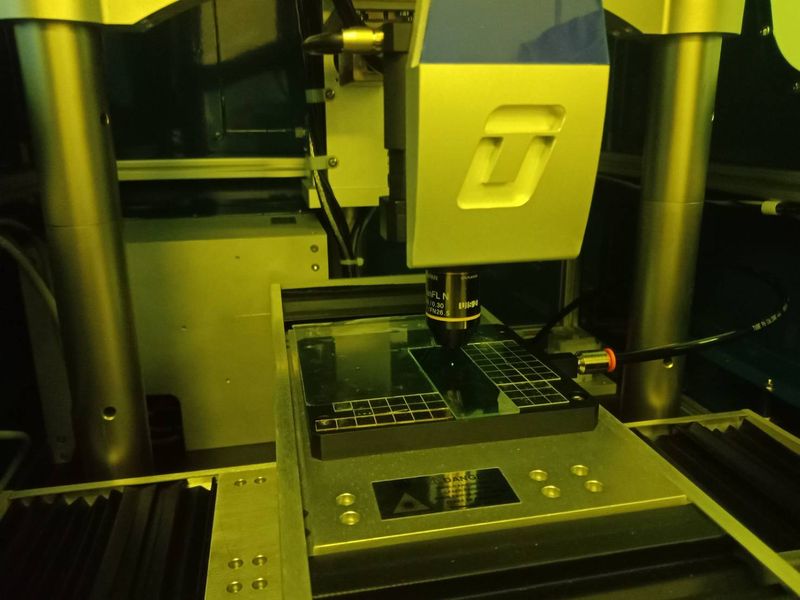

The lactate detector developed by our laboratory employs an ultrasensitive electrochemical biosensor and the enzyme lactate oxidase to accurately measure the levels of lactate in blood samples. The results generated are highly accurate and can be used to facilitate the diagnosis of septicemia by medical professionals. To minimize the amounts of samples and reagents required, our device integrates a polymer-based microfluidic chip that contain microchannels for fluid transport, fabricated using laser lithography. Additionally, the device incorporates several features that enhance its utility, including exceptional portability suitable for bedside usage, and intuitive graphical display of real-time data.

Sperm sorter for assisted reproductive technology

The sperm sorter is a compact device used to select high-quality sperm for assisted reproductive technologies such as intrauterine insemination. The device consists of an easily accessible inlet and outlet, connected by specially designed flow microchannels generated via high-precision laser lithography. Key appeals include compact size, user-friendliness, and structural support made of polydimethyl siloxane (PDMS), which is colorless, elastic, and non-toxic.

ABO and Rh blood typing chip

Fabricated through xerography, this microfluidic blood typing chip requires less than 20 microliters of blood samples to type ABO and Rh blood groups. The device is self-sufficient, needing no additional tools or reagents for sample application and detection. The results are available within 2 minutes, and the chip can be stored for more than 150 days. The performance of this chip in laboratory settings has been rigorously validated and reported in scientific documents, and it is currently entering clinical research. With further development, the chip could potentially be adapted for typing other blood groups or various applications involving agglutination assays.

Service

| NO. | Service type | |

|---|---|---|

| 1. | Sputtering Coater | |

| 1.1. Platinum (99.99%), with the following levels of thickness: 5-10 nm, 10-50 nm, and 50-100 nm | ||

| 1.2. Gold (99.99%), with the following levels of thickness: 5-10 nm, 10-50 nm, and 50-100 nm | ||

| 1.3. Chromium, with the following levels of thickness: 5-10 nm, 10-50 nm, and 50-100 nm | ||

| 2. | Spin coater | |

| 3. | Plasma cleaner | |

| 4. | Programmable laser cutter | |

| 5. | Clean room service | |

| 6. | Microelectrode design | |

| 7. | Microfluidics design | |

| 8. | Production of metal electrodes (Au, Pt) | |

| 9. | Production of master molds for microfluidics | |

| 10. | Evaluation of electrodes using electrochemical techniques |

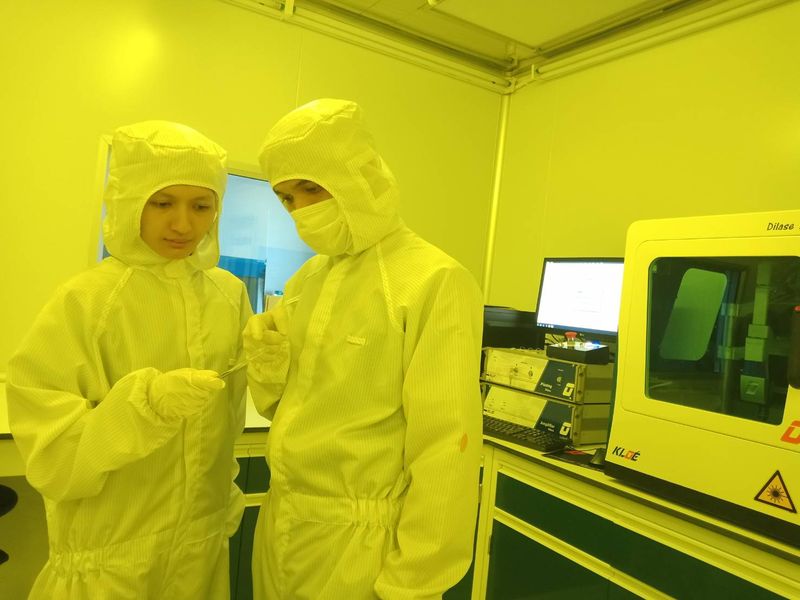

We provide Class 100 clean rooms and general chemistry laboratories certified under the ISO 13485:2016 standard, as well as related instruments. These facilities are well-equipped with necessary resources for a wide range of applications, including microfabrication of master molds with 2-micron precision. Skilled scientists are also available for consultation and technical assistance.

Our expertise

Electrochemical biosensors and microfabrication techniques, such as laser lithography for microchannel fabrication

Equipment and Facilities

- Programmable laser lithography equipment

- Programmable spin coater

- Stereomicroscope

- High resolution - fluorescence microscope

- Duo Sputtering Coater

- Hot-air oven

- Plasma cleaner

- Autoclave machine

- Secure storage for medical devices

Room

A Class 100 clean room with temperature and humidity control systems and dust removal

Contact

Medical Science Research and Innovation Institute https://www.facebook.com/MSRI.PSU/

mblab.psu@gmail.com

+66 7428 9471

Medical Biosensor Laboratory

Medical Science Research and Innovation Institute (MSRI)

6th Floor, Research and Development Office Prince of Songkla University

15 Kanjanavanit Road, Amphoe Hat Yai, Songkhla 90110